Minerals mining is a huge natural

wealth, where mineral resources are optimally utilized if the will is

essential for the continuity of economic growth. In the belly of this

earth to save countless millions metal content and non-metallic

materials that can be utilized as industrial equipment needs of society

at large. Environmental components that have the potential to support

the development of a mining exploration to create jobs. Where mining

exploration activities require the expertise of trained and skilled

professional and technical personnel who may be widely available in

local communities. In addition to the manpower requirements of mineral

properties and mine development activities often require additional

materials and specialized technical services. It is also often provided

by the company’s geological and mining engineering, who seek office in

the local community to participate in exploration and mine development

contract.

Gold prospectors have won a lot

of wealth and there is a finding that smaller-scale artisanal mining and

managed by local residents. Natural resources are very abundant must be

utilized efficiently and should refer also to the security environment.

Because of environmental aspects will have a major impact on mining.

But it also depends on how where we manage these resources.

In the field of extractive metallurgy, mineral engineering,

mineral processing, also known as mineral dressing or ore dressing, is

the process of separating commercially valuable minerals from their

ores. Mineral processing, treating crude ores and mineral products in

order to separate the valuable minerals from the waste rock, or gangue.

It is the first process that most ores undergo after mining in order to

provide a more concentrated material for the procedures of extractive

metallurgy. The primary operations are comminution and concentration,

but there are other important operations in a modern mineral processing

plant, including sampling , analysis and dewatering

SAMPLING AND ANALYSIS

SAMPLING AND ANALYSIS

Routine sampling and analysis of

the raw material being processed are undertaken in order to acquire

information necessary for the economic appraisal of ores and

concentrates. In addition, modern plants have fully automatic control

systems that conduct in-stream analysis of the material as it is being

processed and make adjustments at any stage in order to produce the

richest possible concentrate at the lowest possible operating cost.

SAMPLING

Sampling is the removal from a given lot of material a portion that

is representative of the whole yet of convenient size for analysis. It

is done either by hand or by machine. Hand sampling is usually

expensive, slow, and inaccurate, so that it is generally applied only

where the material is not suitable for machine sampling (slimy ore, for

example) or where machinery is either not available or too expensive to

install. Many different sampling devices are available, including

shovels, pipe samplers, and automatic machine samplers. For these

sampling machines to provide an accurate representation of the whole

lot, the quantity of a single sample, the total number of samples, and

the kind of samples taken are of decisive importance. A number of

mathematical sampling models have been devised in order to arrive at the

appropriate criteria for sampling

ANALYSIS

After one or more samples are taken from an amount of ore

passing through a material stream such as a conveyor belt, the samples

are reduced to quantities suitable for further analysis. Analytical

methods include chemical, mineralogical, and particle size.

Chemical analysis

Even before the 16th century, comprehensive schemes of assaying

(measuring the value of) ores were known, using procedures that do not

differ materially from those employed in modern times. Although

conventional methods of chemical analysis are used today to detect and

estimate quantities of elements in ores and minerals, they are slow and

not sufficiently accurate, particularly at low concentrations, to be

entirely suitable for process control. As a consequence, to achieve

greater efficiency, sophisticated analytical instrumentation is being

used to an increasing extent.

In emission spectroscopy, an electric discharge is established

between a pair of electrodes, one of which is made of the material being

analyzed. The electric discharge vaporizes a portion of the sample and

excites the elements in the sample to emit characteristic spectra.

Detection and measurement of the wavelengths and intensities of the

emission spectra reveal the identities and concentrations of the

elements in the sample.

Mineralogical analysis

A successful separation of a valuable mineral from its ore can be determined by heavy-liquid testing, in which a single-sized fraction of a ground ore is suspended in a liquid of high specific gravity. Particles of less density than the liquid remain afloat, while denser particles sink. Several different fractions of particles with the same density (and, hence, similar composition) can be produced, and the valuable mineral components can then be determined by chemical analysis or by microscopic analysis of polished sections.

Size analysis

A successful separation of a valuable mineral from its ore can be determined by heavy-liquid testing, in which a single-sized fraction of a ground ore is suspended in a liquid of high specific gravity. Particles of less density than the liquid remain afloat, while denser particles sink. Several different fractions of particles with the same density (and, hence, similar composition) can be produced, and the valuable mineral components can then be determined by chemical analysis or by microscopic analysis of polished sections.

Size analysis

Coarsely ground minerals can be classified according to size by

running them through special sieves or screens, for which various

national and international standards have been accepted. One old

standard (now obsolete) was the Tyler Series, in which wire screens were

identified by mesh size, as measured in wires or openings per inch.

Modern standards now classify sieves according to the size of the

aperture, as measured in millimetres or micrometres (10-6 metre).

Mineral processing can involve four general types of unit operation:

COMMINUTION

In all of these processes, the most important considerations are the economics of the processes and this is dictated by the grade and recovery of the final product. To do this, the mineralogy of the ore needs to be considered as this dictates the amount of liberation required and the processes that can occur. The smaller the particles processes, the greater the theoretical grade and recovery of the final product, but this however is difficult to do with fine particles as they prevent certain concentration processes from occurring.

In order to separate the valuable components of an ore from

the waste rock, the minerals must be liberated from their interlocked

state physically by comminution. As a rule, comminution begins by

crushing the ore to below a certain size and finishes by grinding it

into powder, the ultimate fineness of which depends on the fineness of

dissemination of the desired mineral. Whereas crushing is done mostly

under dry conditions, grinding mills can be operated both dry and wet,

with wet grinding being predominant.

CONCENTRATION

Concentration involves the separation of valuable minerals from the other raw materials received from the grinding mill. In large-scale operations this is accomplished by taking advantage of the different properties of the minerals to be separated. These properties can be colour (optical sorting), density (gravity separation), magnetic or electric (magnetic and electrostatic separation), and physicochemical (flotation separation). There are a number of ways to increase the concentration of the wanted minerals: in any particular case the method chosen will depend on the relative physical and surface chemical properties of the mineral and the gangue. Concentration is defined as the number of moles of a solute in a volume of the solution. In case of mineral processing concentration means the increase of the percentage of the valuable mineral in the concentrate.

Gravity separation is the separation of two or more minerals of different specific gravity by their relative movement in response to the force of gravity and one or more other forces (such as centrifugal forces, magnetic forces, buoyant forces), one of which is resistance to motion (drag force) by a viscous medium such as heavy media, water or, less commonly, air. Gravity separation is one of the oldest technique in mineral processing but has seen a decline in its use since the introduction of methods like flotation, classification, magnetic separation and leaching. Gravity separation dates back to at least 3000 BC when Egyptians used the technique for separation of gold.

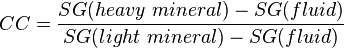

It is necessary to determine the suitability of a gravity

concentration process before it is employed for concentration of an ore.

The concentration criterion is commonly used for this purpose, designated  in the following equation (where

in the following equation (where  represents specific gravity):

represents specific gravity):

in the following equation (where

in the following equation (where  represents specific gravity):

represents specific gravity):- for CC > 2.5, suitable for separation of particles above 75 micron in size

- for 1.75 < CC < 2.5, suitable for separation of particles above 150 micron in size

- for 1.50 < CC < 1.75, suitable for separation of particles above 1.7 mm in size

- for 1.25 < CC < 1.50, suitable for separation of particles above 6.35 mm in size

- for CC < 1.25, not suitable for any size

Gravity methods use the difference in the density of minerals

as the concentrating agent. In heavy-media separation (also called

sink-and-float separation), the medium used is a suspension in water of a

finely ground heavy mineral (such as magnetite or arsenopyrite) or

technical product (such as ferrosilicon). Such a suspension can simulate

a fluid with a higher density than water. When ground ores are fed into

the suspension, the gangue particles, having a lower density, tend to

float and are removed as tailings, whereas the particles of valuable

minerals, having higher density, sink and are also removed. The

magnetite or ferrosilicon can be removed from the tailings by magnetic

separation and recycled.

In the process called jigging, a water stream is pulsed, or moved

by pistons upward and downward, through the material bed. Under the

influence of this oscillating motion, the bed is separated into layers

of different densities, the heaviest concentrate forming the lowest

layer and the lightest product the highest. Important to this process is

a thorough classification of the feed, since particles less than one

millimetre in size cannot be separated by jigging.

Finer-grained particles (from 1 millimetre to 50 micrometres) can

be effectively separated in a flowing stream of water on horizontal or

inclined planes. Most systems employ additional forces—for example,

centrifugal force on spirals or impact forces on shaking tables. Spirals

consist of a vertical spiral channel with an oval cross section. As the

pulp flows from the top to the bottom of the channel, heavier particles

concentrate on the inner side of the stream, where they can be removed

through special openings. Owing to their low energy costs and simplicity

of operation, the use of spirals has increased rapidly. They are

especially effective at concentrating heavy mineral sands and gold ores.

Gravity concentration on inclined planes is carried out on shaking

tables, which can be smoothed or grooved and which are vibrated back and

forth at right angles to the flow of water. As the pulp flows down the

incline, the ground material is stratified into heavy and light layers

in the water; in addition, under the influence of the vibration, the

particles are separated in the impact direction. Shaking tables are

often used for concentrating finely grained ores of tin, tungsten,

niobium, and tantalum.

FROTH FLOTATION

Froth flotation is an important concentration process. This process can be used to separate any two different particles and operated by the surface chemistry of the particles. In flotation, bubbles are introduced into a pulp and the bubbles rise through the pulp. In the process, hydrophobic particles become bound to the surface of the bubbles. The driving force for this attachment is the change in the surface free energy when the attachment occurs. These bubbles rise through the slurry and are collected from the surface. To enable these particles to attach, careful consideration of the chemistry of the pulp needs to be made. These considerations include the pH, Eh and the presence of flotation reagents. The pH is important as it changes the charge of the particles surface and the Eh affects the chemisorption of collectors on the surface of the particles.

Flotation is the most widely used method for the concentration

of fine-grained minerals. It takes advantage of the different

physicochemical surface properties of minerals—in particular, their

wettability, which can be a natural property or one artificially changed

by chemical reagents. By altering the hydrophobic (water-repelling) or

hydrophilic (water-attracting) conditions of their surfaces, mineral

particles suspended in water can be induced to adhere to air bubbles

passing through a flotation cell or to remain in the pulp. The air

bubbles pass to the upper surface of the pulp and form a froth, which,

together with the attached hydrophobic minerals, can be removed. The

tailings, containing the hydrophilic minerals, can be removed from the

bottom of the cell.

The addition of flotation reagents also affects the operation

of these processes. The most important chemical that is added is the

collector, This chemical binds to the surface of the particles as it is a

surfactant. The main considerations in this chemical is the nature of

the head group and the size of the hydrocarbon chain. The hydrocarbon

tail needs to be short to maximize the selectivity of the desired

mineral and the headgroup dictates which minerals it attaches to. The

frothers are another important chemical addition to the pulp at it

enables stable bubbles to be formed. This is important as if the bubble

coalesce, minerals fall off their surface. The bubbles however should

not be too stable as this prevents easy transportation and dewatering of

the concentrate formed. The mechanism of these frothers is not

completely known and further research into their mechanisms is being

performed.

Depressants and activators are used to selectively separate

one mineral from another. Depressants inhibit the flotation of one

mineral or minerals while activators enable the flotation of others.

Examples of these include CN−, used to depress all sulfides but galena

and this depressant is believed to operate by changing the solubility of

chemisorbed and physisorbed collectors on sulfides. This theory

originates from Russia. An example of an activator is Cu2+ ions, used

for the flotation of sphalerite. There are a number of cells able to be

used for the flotation of minerals. these include flotation columns and

mechanical flotation cells. The flotation columns are used for finer

minerals and they typically have a higher grade and lower recovery of

minerals than mechanical flotation cells. The cells in use at the moment

can exceed 300 m3. This is done as they are cheaper per unit volume

than smaller cells, but they are not able to be controlled as easily as

smaller cells.

Flotation makes possible the processing of complex

intergrown ores containing copper, lead, zinc, and pyrite into separate

concentrates and tailings—an impossible task with gravity, magnetic, or

electric separation methods. In the past, these metals were recoverable

only with expensive metallurgical processes.

MAGNETIC SEPARATION

Magnetic separation is a process in which magnetically

susceptible material is extracted from a mixture using a magnetic force.

This separation technique can be useful in mining iron as it is

attracted to a magnet. In this machine the raw ore, after calcination

was fed onto a moving belt which passed underneath two pairs of

electromagnets under which further belts ran at right angles to the feed

belt. The first pair of electromagnets was weakly magnetised and served

to draw off any iron ore present. The second pair were strongly

magnetised and attracted the wolframite, which is weakly magnetic. These

machines were capable of treating 10 tons of ore a day.This process of

separating magnetic substances from the non-magnetic substances in a

mixture with the help of a magnet is called magnetic separation.

Magnetic separation is based on the differing degrees of

attraction exerted on various minerals by magnetic fields. Success

requires that the feed particles fall within a special size spectrum

(0.1 to 1 millimetre). With good results, strongly magnetic minerals

such as magnetite, franklinite, and pyrrhotite can be removed from

gangue minerals by low-intensity magnetic separators. High-intensity

devices can separate oxide iron ores such as limonite and siderite as

well as iron-bearing manganese, titanium, and tungsten ores and

iron-bearing silicates.

This process operates by moving particles in a magnetic

field. The force experienced in the magnetic field is given by the

equation f=m/k.H.dh/dx. with k=magnetic susceptibility, H-magnetic field

strength, and dh/dx being the magnetic field gradient. As seen in this

equation, the separation can be driven in two ways, either through a

gradient in a magnetic field or the strength of a magnetic field. The

different driving forces are used in the different concentrators. These

can be either with water or without. Like the spirals, washwater aids in

the separation of the particles while increases the entrainment of the

gangue in the concentrate.

ELECTROSTATIC SEPARATION

The electrostatic method separates particles of different

electrical charges and, when possible, of different sizes. When

particles of different polarity are brought into an electrical field,

they follow different motion trajectories and can be caught separately.

Electrostatic separation is used in all plants that process heavy

mineral sands bearing zircon, rutile, and monazite. In addition, the

cleaning of special iron ore and cassiterite concentrates as well as the

separation of cassiterite-scheelite ores are conducted by electrostatic

methods.

There are two main types of electrostatic separators. These

work in similar ways, but the forces applied to the particles are

different and these forces are gravity and electrostatic attraction. The

two types are electrodynamic separators (or high tension rollers) or

electrostatic separators. In high tension rollers, particles are charged

by a corona discharge. This charges the particles that subsequently

travel on a drum. The conducting particles lose their charge to the drum

and are removed from the drum with centripetal acceleration.

Electrostatic plate separators work by passing a stream of particles

past a charged anode. The conductors lose electrons to the plate and are

pulled away from the other particles due to the induced attraction to

the anode. These separators are used for particles between 75 and 250

micron and for efficient separation to occur, the particles need to be

dry, have a close size distribution and uniform in shape. Of these

considerations, one of the most important is the water content of the

particles. This is important as a layer of moisture on the particles

will render the non-conductors as conductors as the layer of the water

is conductive.

Electrostatic plate separators are usually used for streams

that have small conductors and coarse non-conductors. The high tension

rollers are usually used for streams that have coarse conductors and

fine non-conductors. These separators are commonly used for separating

mineral sands, an example of one of these mineral processing plants is

the CRL processing plant at Pinkenba in Brisbane Queensland. In this

plant, zircon, rutile and ilmenite are separated from the silica gangue.

In this plant, the separation is performed in a number of stages with

roughers, cleaners, scavengers and recleaners.

DEWATERING

Dewatering is an important process in mineral processing. The purpose of dewatering is to remove water absorbed by the particles which increases the pulp density. This is done for a number of reasons, specifically, to enable ore handling and concentrates to be transported easily, allow further processing to occur and to dispose of the gangue. The water extracted from the ore by dewatering is recirculated for plant operations after being sent to a water treatment plant. The main processes that are used in dewatering include dewatering screens such as Sepro-Sizetec Screens, sedimentation, filtering, and thermal drying. These processes increase in difficulty and cost as the particle size decreases.

Dewatering screens operate by passing particles over a screen.

The particles pass over the screen while the water passes through the

apertures in the screen. This process is only viable for coarse ores

that have a close size distribution as the apertures can allow small

particles to pass through

Sedimentation operates by passing water into a large thickener or

clarifier. In these devices, the particles settle out of the slurry

under the effects of gravity or centripetal forces. These are limited by

the surface chemistry of the particles and the size of the particles.

To aid in the sedimentation process, flocculants and coagulants are

added to reduce the repulsive forces between the particles. This

repulsive force is due to the double layer formed on the surface of the

particles. The flocculants work by binding multiple particles together

while the coagulants work by reducing the thickness of the charged layer

on the outside of the particle.

Thermal drying is usually used for fine particles and to

remove low water content in the particles. Some common processes include

rotary dryers, fluidised beds, spray driers, hearth dryers and rotary

tray dryers. This process is usually expensive to operate due to the

fuel requirement of the dryers.